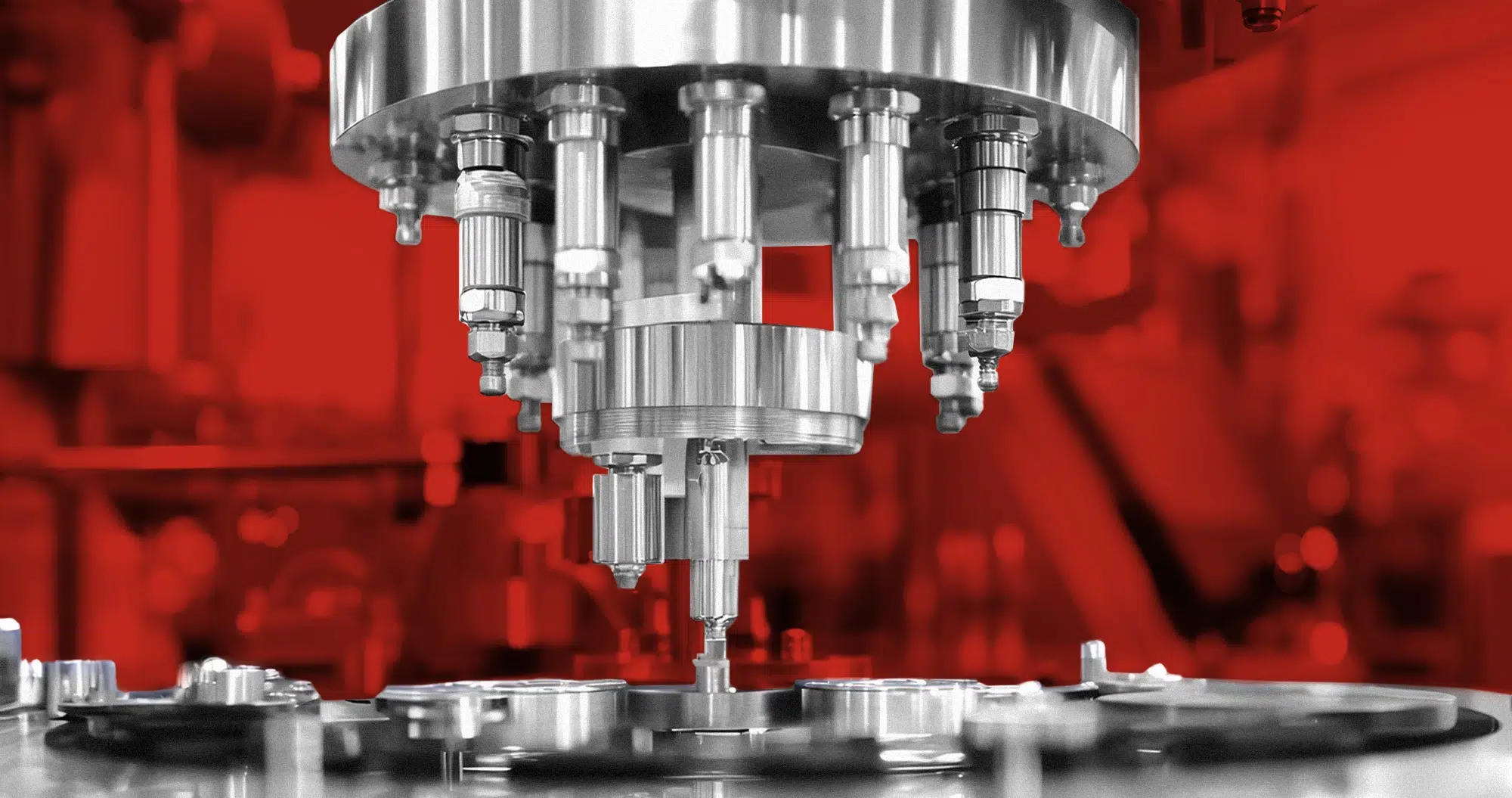

Filling machines rely on smooth and continuous operation to ensure optimal productivity, which is where a slip ring proves beneficial. Slip rings allow for the seamless […]

Filling machines rely on smooth and continuous operation to ensure optimal productivity, which is where a slip ring proves beneficial. Slip rings allow for the seamless transfer of power and data between rotating and stationary parts of a machine, making them essential in various industrial applications, including filling machines. This article will explore the different types of slip rings suitable for filling machines and help choose the best solution for your needs.

Slip Ring Overview

A slip ring is an electromechanical component that enables the transfer of electrical signals or power between rotating and stationary parts. In the context of filling machines, slip rings play a crucial role in ensuring a steady and reliable power supply and data transmission while the system is in motion. With continuous contact through conductive rings and brushes, slip rings ensure seamless communication and energy flow, making them essential for the uninterrupted operation of filling machines. The type of slip ring required can vary depending on the machine’s design and the specific environmental conditions in which it operates.

Types of Slip Ring for Filling Machines

Filling machines can vary in their design, speed, and complexity. Therefore, selecting the right slip ring is essential for ensuring reliable and continuous operation. The following are slip ring options that are ideal for filling machines:

Capsule Slip Rings

Capsule slip rings are compact and highly reliable, making them ideal for applications with limited space. These slip rings offer a high level of protection against dust and moisture, making them perfect for filling machines that need to operate in challenging environments. Capsule slip rings are ideal because of their efficiency and small size and are therefore utilized in sensitive and small-sized filling machine designs.

Key benefits:

- Space-saving design

- Customizable options

- IP65-rated

- High circuit density

Faston Slip Rings

Faston slip rings are intended for easy installation and quick maintenance and are, therefore, preferred in filling machines where there is frequent adjustment or maintenance. They allow for quick and easy connection, which ensures high efficiency and minimum downtime. The faston terminals also offer a high efficiency and simple connection, thus ensuring high productivity and low downtime. They are appropriate for high-volume machines, which require high efficiency.

Key benefits:

- Space-efficient design

- IP65-rated

- Easy to install

Through-Bore Slip Rings

For filling machines with large rotating shafts, through-bore slip rings are ideal. Through-bore slip rings provide the capability of allowing cables or other components to pass through the center, providing added utility and ease. With high power handling capabilities and a heavy-duty design, through-bore slip rings are ideally suited for heavy-duty filling machines with power and data transfer needs.

Key benefits:

- Hollow shaft design

- IP65-rated

- High data rate

- Customizable in size and type of cable

- Easy to integrate in a fluidic joint

Ruggedized Slip Rings

Filling machines operating in harsh environments, like those subjected to extreme temperatures or vibrations, need ruggedized slip rings. These ruggedized slip rings are designed to survive the most challenging conditions and provide superior durability. In food packaging, chemical processing, or pharmaceutical applications, ruggedized slip rings deliver the reliability to ensure your filling machine operates without disruption.

Key benefits:

- IP65-rated

- Customizable options

- High data-rate

Open Slip Rings

Open slip rings are ideal for use where flexibility and ease of operation are needed. Open slip rings are commonly used on filling machines where power or data transmission is needed without complex protective housing. While they do require more attention to environmental factors, open slip rings are cost-effective and straightforward to maintain.

Key benefits:

- Tailored options

- Frameless design

- Hollow shaft configuration

Flat Slip Rings

Flat slip rings are a great solution in certain filling machine applications where there is little space. Flat slip rings have a flat design that is highly space-efficient, so they can be used in machines where cylindrical slip rings might not fit. Flat slip rings provide reliable power and signal transmission, ensuring your filling machine runs smoothly.

Key benefits:

- Compact design

- Hollow shaft configuration

How to Choose the Right Slip Ring for Your Filling Machine

Choosing the right slip ring for your filling machine depends on many factors like machine type, working conditions, and desired performance. Here are a few key things to consider when selecting a slip ring for filling machines:

- Space Restrictions: If your filling machine has limited space or limited space, a capsule or flat slip ring would be a suitable choice for more space savings.

- Environmental Factors: Equipment exposed to harsh conditions, such as exposure to extreme temperatures or humidity, would be better protected with ruggedized or capsule slip rings.

- Power Requirements: High-power filling machines may benefit from through-bore slip rings, which can handle larger cables and power demands.

- Maintenance Needs: If your filling machine requires frequent maintenance or adjustments, faston slip rings provide easy installation and quick serviceability.

Conclusion

Selecting the right slip ring for your filling machine is important for ensuring reliable, efficient, and continuous operation. Whether you opt for a compact capsule slip ring, a ruggedized model for harsh environments, or a through-bore slip ring for larger machines, choosing the right solution can boost productivity and reduce downtime. By understanding the different types of slip rings and their benefits, you can make an informed choice that can enhance the performance of your filling machine.