This white paper outlines the pros and cons associated with centralized and decentralized drives for motion control applications. The intention is not to favor one approach […]

This white paper outlines the pros and cons associated with centralized and decentralized drives for motion control applications. The intention is not to favor one approach over another since, in many cases, each will have applications for which it is best suited. Instead, the idea is to make machine builders and engineers aware of the specific advantages and disadvantages that can contribute to project success.

Introduction

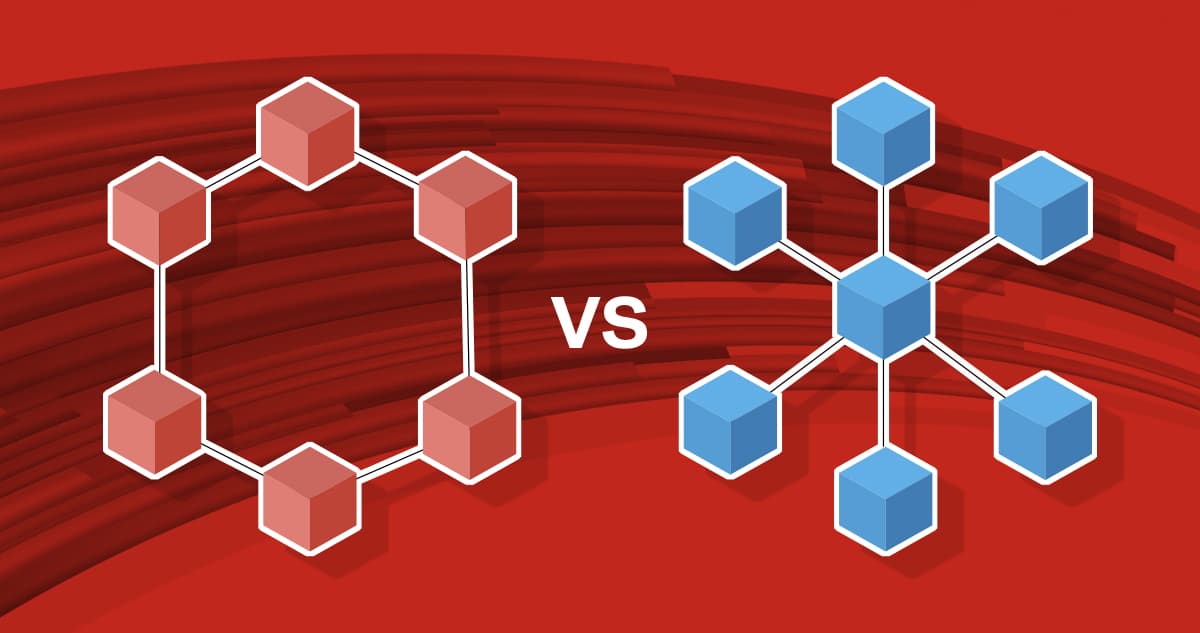

Choosing a centralized configuration means that the driver and all other components required for motion control are housed within a cabinet, usually located near machines and production lines worldwide. In contrast, by choosing a decentralized (or distributed) architecture, the drive technology is transferred from the control cabinet at a much shorter distance to the motion control process-sometimes even being integrated with the motor itself.

Of course, there are varying degrees of decentralization, from a single soft starter or drive located on the motor to an entire decentralized system, which may include, for example, a VFD, overload protection, a motor disconnect, an I/O module, and a bus module. In many cases, this equipment can be supplied as a “package” from a single supplier.

Centralized and decentralized architectures have their merits and demerits. Deciding which is best depends greatly on the specific application. On closer inspection, mixed-architecture systems are quite common in the industry, especially when the drives share some common characteristics, thus demonstrating the validity of a hybrid approach.

The following chapters outline some of the most significant pros and cons associated with centralized and decentralized drive strategies, focusing on aspects such as cabinet/control panel size, application sizing, options, and modularity.

Dimensions of the cabinet/control panel

As is often the case in an increasing number of industrial applications, space is a constraining factor. With a centralized approach-if, space permits-all drives can be placed within a single cabinet, thus simplifying diagnostics and maintenance. In addition, it may be possible to centralize some services, such as cooling, power distribution, and safety. Visual inspection is one of the advantages should you opt for centralized motion control.

Of course, all this centralization comes at a price: the footprint or dimensional envelope of the cabinet increases. With many factories and plants having space problems, machine builders are less and less inclined to have bulky control cabinets. A small footprint has become a major selling point for OEMs in recent years. Not least, footprint issues may arise when upgrading or expanding existing machinery, for example, to eliminate bottlenecks or increase efficiency. Under these circumstances, engineers often have to contend with limited space or space allocated for something else.

Another factor to consider is the significant cost of material and labor represented by the control cabinet, which is usually designed specifically for the application. Therefore, the cost associated with the design, construction, and installation of a centralized system must be a paramount consideration in the overall expense of the machine.

Housing the drives in a cabinet separate from the machine naturally provide complete protection from the external environment of the plant or factory. However, since heat loss is generated centrally, effective cooling is needed inside the control cabinet.

When a decentralized drive strategy is adopted, the size of the main control cabinet is usually extremely compact, while installation costs are lower in terms of material and workmanship. An additional advantage is that distributed drives involve pre-wired cables, which reduces the possibility of error and shortens commissioning time.

Of course, a decentralized system is particularly suitable for simple stand-alone motor control, but that is not all. Because the drive can be mounted on or near the machine/motor, the advantages of size reduction are glaring compared to an equivalent centralized system. The cost reduction also eliminates a custom control panel, not to mention the labor required to assemble and install the system. In addition, wiring lengths are reduced, while further benefits include improved electromagnetic compatibility (EMC) and capillary distribution of heat losses, reducing the need for and cost of a centralized temperature control system.

While some believe this type of architecture is not robust enough to provide a high degree of protection against the surrounding environment, the opposite is true. Many of the latest decentralized drives offer embedded features and a high IP66/NEMA 4X protection to allow installation directly on or near the motor. The robust design of decentralized drives can protect against penetration by dust or water jets and offer greater safety guarantees for technicians working in contact with live parts.

There are a few drawbacks to using decentralized drives in this area, although visual inspection and maintenance are sometimes more complex since the drives are difficult to access.

| Cabinet/control panel dimensions | Centralized | Decentralized |

| Size | ✓ | |

| Service centralization | ✓ | |

| Visual inspection | ✓ | |

| Materials cost | ✓ | |

| Labor cost | ✓ | |

| Accessibility | ✓ |

Application sizing

One of the main advantages of centralized solutions in application sizing is that the motors are not subject to any derating. To provide a standard definition, severe operating conditions require derating the motor. Such conditions may include an ambient temperature above 40°C, motor mounting location, drive switching frequency, or oversizing of the drive chosen for the motor.

Derating is a design process that can contribute significantly to machine reliability. With a centralized approach, smaller motor sizes and lower rotor inertia are typical, while achievable performance is higher than with decentralized solutions. As for shortcomings, those who opt for a centralized solution will have to consider longer wiring. Each motor is connected to the control cabinet via two cables, one for power and one for feedback.

Those who think that decentralized motion control solutions do not lend themselves to optimal application sizing would be mistaken. For example, in some cases, it is possible to use a standard cabinet for basic functions and add optional independent modules (with their onboard electronics) without having to modify the original cabinet.

In some cases, an architecture with decentralized drives may be necessitated by the size of the machine. Long motor cables can be eliminated from a central control cabinet by bringing power to decentralized drives with a daisy chain, drive-to-drive, or an integrated power supply. In addition, decentralized drives can simplify structuring even in large, complex machines, a particular advantage for applications in industries such as automotive and intralogistics.

However, there is a potential disadvantage to decentralized solutions regarding application sizing. A motor derating due to heat exchange with the drive must be accepted in motors with integrated drives. To counter this problem, for the same T,n performance, the motor with the integrated drive will have a bulkier design (T,n is the ratio of rotational speed to torque). It should be noted, however, that this requirement is not necessary for nearby decentralized drives.

| Application sizing | Centralized | Decentralized |

| Motor derating | ✓ | ✓ (with nearby) |

| Motor cable length | ✓ |

Options

In terms of options, centralized solutions tend to offer greater customization of modules within the cabinet. This type of framework solution also ensures that options can be added in the field at a later date. Although the most common options-such as STO (Safe Torque Off), Safety Bus, I/O, and real-time Ethernet protocols, are available for decentralized systems, they are limited compared to the framework solutions due to limited space. Typically, options are installed by the OEM and cannot be added or removed in the field.

| Options | Centralized | Decentralized |

| Safety via Bus | ✓ | ✓ |

| Options scalability | ✓ |

Modularity

Centralized systems are considered less modular than their distributed counterpart, although there is more flexibility concerning heat dissipation systems based on air or liquid cooling. In general, the modularity of the control panel is not related to the modularity of the overall system.

In contrast, decentralized configurations are highly modular. Here, the architecture of the drives can follow the mechanical modularity of the machine or system, with the obvious advantages that come with it.

It can be said that today’s machines and factories are increasingly being created based on modularity, mainly because modular systems facilitate reduced development costs and shorter lead times. The industry has been looking for solutions to increase process automation without increasing the space occupied by switchboards.

Decentralized drives can be placed where needed and, thanks to integrated I/O, can solve challenging tasks without adding terminals, saving time and money.

| Modularity | Centralized | Decentralized |

| Modularity | ✓ | |

| Flexibility of the dissipation system | ✓ |

Network functionality

Many of the latest drives offer an optional communication network and I/O modules that are quick and easy to install, allowing the standard drive to be adapted to individual user applications. Plug-and-drive communication via real-time Ethernet networks is also increasingly common with today’s drive technology. Plug-in interfaces for protocols such as Profinet and EtherCAT allow the drives to be seamlessly integrated into the end user’s existing communication networks.

For those considering a distributed approach, using a decentralized PLC module alongside decentralized drives reduces the load on the higher-level controller. It creates, in some applications, the basis for truly modular machines without control cabinets. Such PLC modules will typically be equipped with RTOS (Real-Time Operating Software) to provide decentralized intelligence with network capability provided by a selection of communication protocols. Flexibility in design and predisposition to modularity is thus assured.

| Network functionality | Centralized | Decentralized |

| PLC performance | ✓ | |

| RT ethernet communication | ✓ | ✓ |

Investment costs

It is difficult to directly compare savings between centralized and decentralized solutions, partly because each application is different. In some simple, isolated cases, the decision between centralization and decentralization may be obvious. However, evaluating the options for a production line where every step in the process depends on other devices greatly increases the complexity level.

Those in favor of purely distributed systems argue that more than 30 percent of costs can be saved compared to a centralized solution because of longer design time, more components and wiring, larger panels and PLCs, and slower installation and commissioning.

However, always check your specific needs with a specialist and ask him or her for advice, as each project has characteristics that can influence the decision-making process if the goal is to achieve an optimal result.

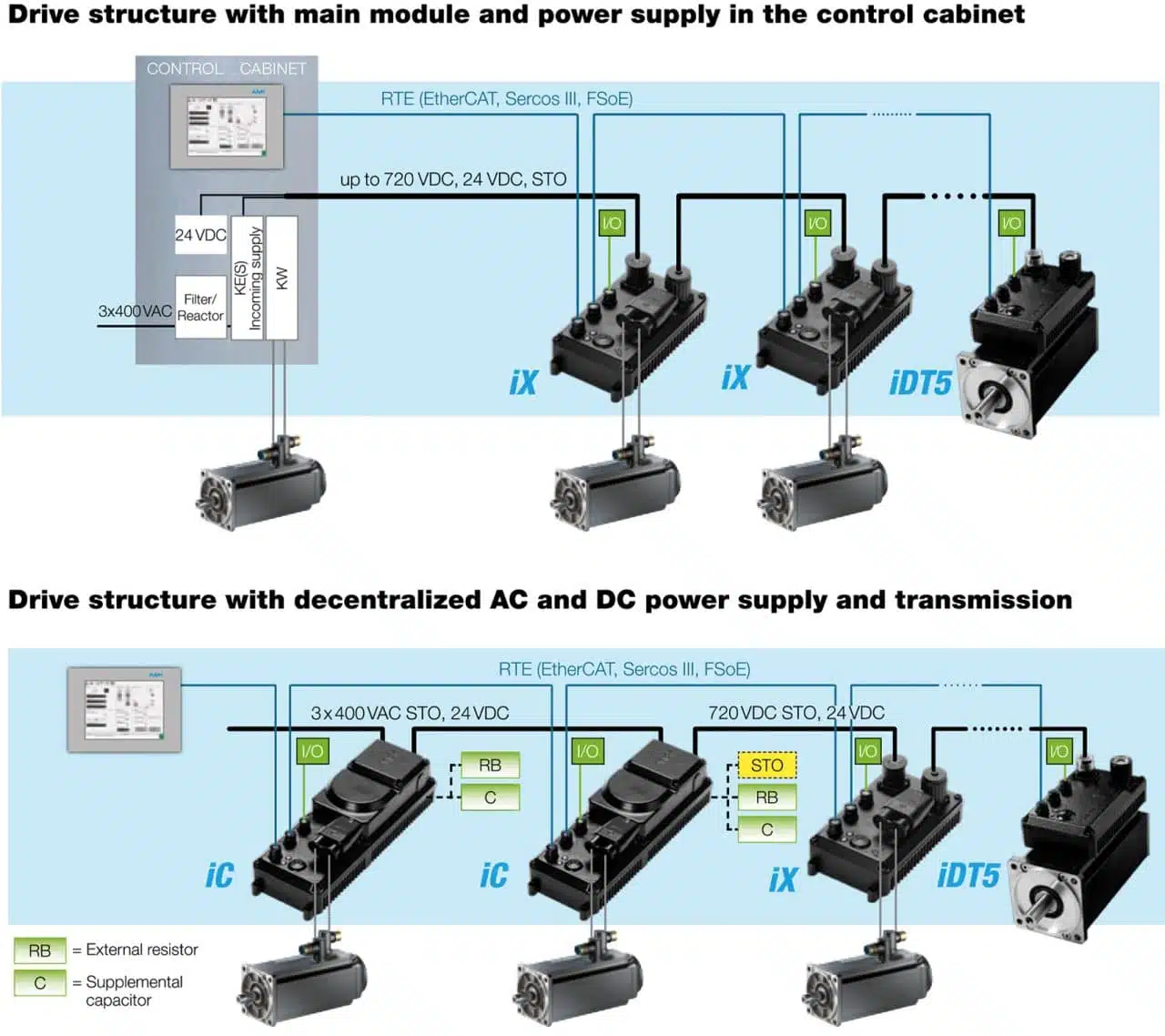

Product Solutions

Among the many product solutions available from Servotecnica is the AMK iC/iX series of distributed brushless drives. For example, the AMKASMART iC decentralized servo drive with integrated power supply is optimized for use in single-axis applications and modular machine structures. With the integration of a power supply module, the need for a control cabinet is virtually eliminated to facilitate a flexible machine solution.

The AMKASMART iX decentralized servo drive, just like the iC, is designed for rotary and linear synchronous and asynchronous motors of various types. However, power supply and communication are looped from module to module in this case.

With AMKASMART drives, it is possible to combine AMK’s various distributed solutions on the machine or production line and thus choose between decentralized and centralized solutions or use the two types together. After all, there is no one-size-fits-all solution.

Other decentralized products from Servotecnica include the AMKASMART i3X servo motors (three decentralized servo controllers in one housing), the AMKASMART iDT5 and iDT7 servo motors with integrated servo drives, and the AMKASMART iSA controller that has an input power supply to facilitate automation without the need for a separate power supply.