The French Alternative Energies and Atomic Energy Commission (CEA) is using an electrical rotary joint (slip ring) that was specially devised by Servotecnica for use in […]

The French Alternative Energies and Atomic Energy Commission (CEA) is using an electrical rotary joint (slip ring) that was specially devised by Servotecnica for use in cryogenic turbulence tests that form part of the SHREK (Superfluid high REynolds von Kármán) experiment. Servotecnica’s slip ring had to transfer torque gauge signals in such a way that the friction torque of brushes on the rings did not affect measurements.

CEA is a key player in research, development and innovation across four principal areas: defence and security; low carbon energies (nuclear and renewable energies); technological research for industry; and fundamental research in physical and life sciences. Drawing on its expertise, CEA actively participates in collaborative projects with a large number of academic and industrial partners. The organisation has nine facilities spread throughout France, where it works in partnership with many other research bodies, local authorities and universities.

One of CEA’s current areas of research focus is turbulence, which is a highly important phenomenon for practical purposes. Very different problems have their origin in turbulence; a diversity which originates from a lack of understanding on a global level. In comparison, pressure, temperature and density are sufficient for describing the rest state of a gas, despite the intractable complexity of molecular collisions. However, a simple hypothesis such as molecular chaos does not exist in turbulence. Instead, complete velocity field calculations are required. If such calculations could be avoided and replaced with random sampling having all these correlations, the time saving would be enormous, a potential benefit that prompted CEA to commence this research.

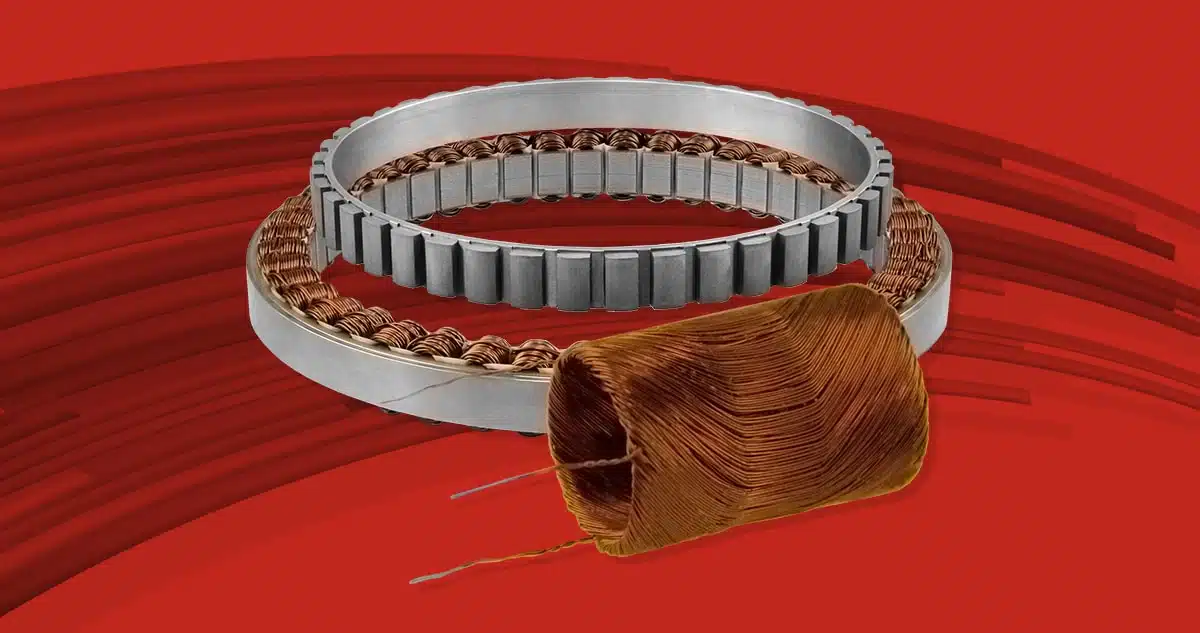

Within CEA’s Low Temperature Department (SBT), special apparatus has been constructed to study turbulence from ambient down to temperatures as low as 1.6K (in liquid helium). The von Kármán flow is produced in a cylindrical cell measuring 1.16m in height and 0.78m in diameter. Specifically, flow is generated by two bladed disks, each 0.72m in diameter. A cold torque meter is inserted as close as possible to the impeller in order to gather accurate torque measurements.

The SHREK experiment requires precise and complex measurement devices that are typically unavailable as standard solutions. As a result, custom-made systems are required, a case in point being the aforementioned cold torque meter, which is essentially an industrial toque meter modified to work at the exceptionally low temperatures required for cryogenic experiments.

It was important that the very low readings taken by the cold torque meter were not influenced by the torque of kinematic assembly components such as bearings or gearboxes. For this reason, SBT set about developing its own cold torque meter featuring mechanical and electrical components optimised to work at low temperatures. Among such parts is the special slip ring, through which torque gauge signals have to be transferred without any influence from ring-brush friction.

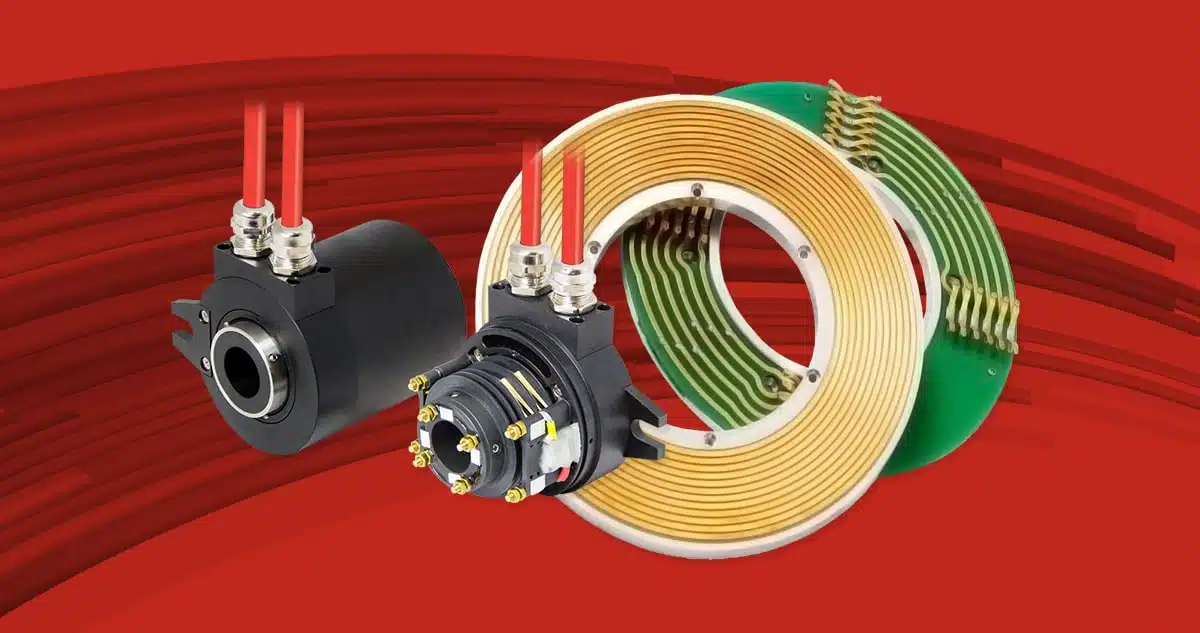

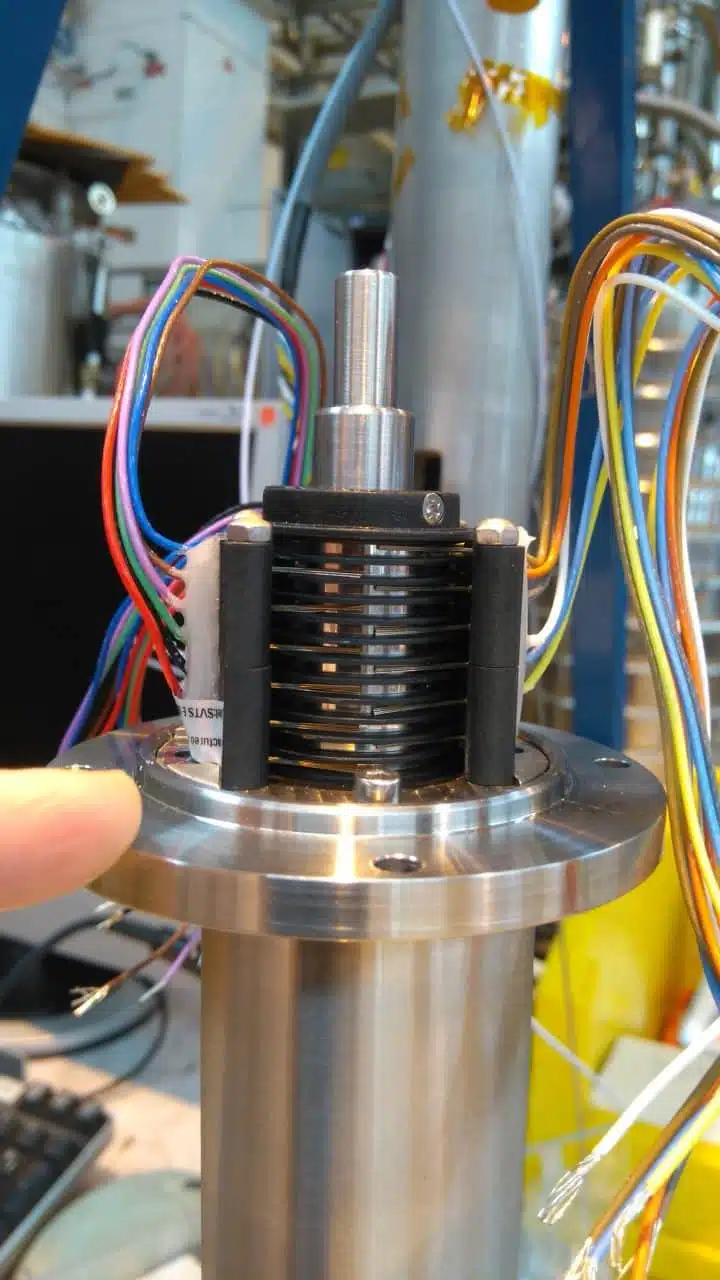

Servotecnica set about specifying a customised frameless slip ring that only comprised the 12 ABS rings, shaft and brush holders; the bearing was omitted as its grease lubricant would not be able to withstand the low temperatures (an alternative solution was implemented). In addition, the slip ring wires were Teflon insulated. This cost-effective solution allowed quick and easy integration within the SHREK experiment apparatus.

In terms of slip-ring performance, the first tests at 4.2K (-269°C) showed normal operation for a duration of 1 hour at a maximum rotational speed of 90 rpm. Importantly, no visible material degradation was observed.

The choice of contact material is fundamental in slip-ring performance. Suitable wear resistance is paramount, even more so in cryogenic conditions. A deteriorating contact area could compromise the transmission of torque signals during the tests at SBT. Moreover, premature wear could lead to potential system damage, which in the case of the customised apparatus developed for the SHREK experiment, would prove extremely costly. On a further material issue, it was determined that the best results would be obtained with gold-plated surfaces to aid low contact resistance and low noise conditions.

Operating conditions were another key consideration for Servotecnica’s engineers. The presence of such low temperatures helped identify issues like the inability of standard bearing grease to function as required. An additional factor centred on orientation, namely if the slip ring is to be mounted vertically or horizontally during operation (the SHREK experiment apparatus required a vertical slip ring). Depending on the plane in which the slip ring is mounted, there are particular mechanical precautions to take into account, typically involving components such as housings and bearings.

Despite the technical challenges involved in supplying a slip ring for this demanding application, Servotecnica describes its solution as relatively simple. As a result, the slip ring could be delivered to the customer in a short lead-time. This factor proved to be important, as SBT had already developed its cold torque meter and was waiting on the slip ring to begin tests.

Following installation of the slip ring, the experiments have led to the solving of major technological challenges involving turbulence, including safety issues, driving large impellers and heat removal in sub-cooled superfluid conditions. In addition, the largest Reynolds (Re) numbers ever achieved in a von Kármán cell have been obtained both in normal and superfluid conditions (the Re number is an important dimensionless quantity in fluid dynamics that helps predict flow patterns in different situations). Crucially, torque measurements in these conditions are consistent with those performed in water cells of similar aspect ratio for which the Re number is far smaller (two orders of magnitude smaller than SHREK).