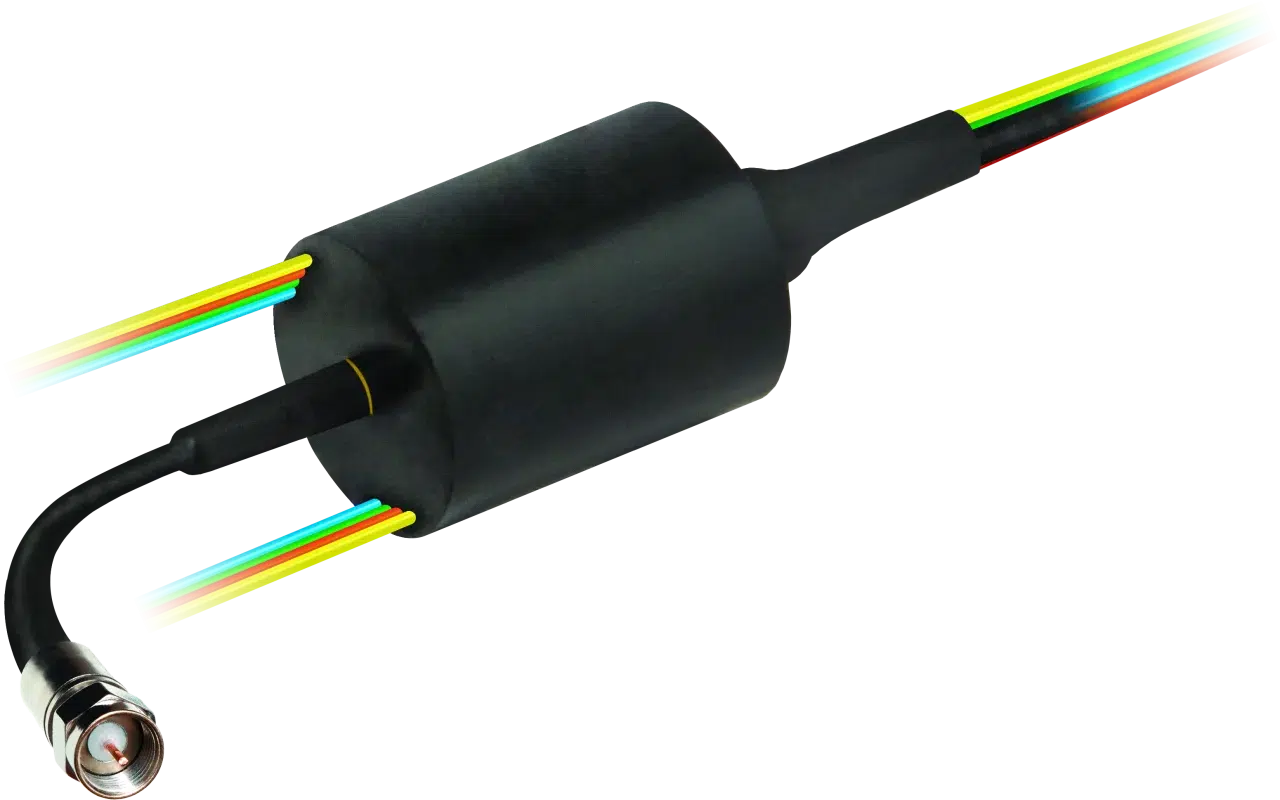

Slip rings are vital components for camera systems that require continuous rotation, such as pan-tilt-zoom (PTZ) cameras, robotic mounts, or drones. These devices enable the transmission […]

Slip rings are vital components for camera systems that require continuous rotation, such as pan-tilt-zoom (PTZ) cameras, robotic mounts, or drones. These devices enable the transmission of power and signals between stationary and rotating parts. Choosing the right slip ring is important to maintaining system performance and reliability. Here’s what engineers need to consider when selecting slip rings for camera systems.

The first step is understanding the specific requirements of your camera system. It’s essential to account for the type and volume of signals being transmitted. Camera systems often handle a mix of power, video, and control signals. For instance, transmitting high-definition video or Ethernet data may require slip rings with advanced shielding and bandwidth capabilities to preserve signal integrity.

Another important consideration is the physical constraints of your system. Compact and lightweight slip rings are particularly advantageous for applications like drones, where minimizing payload weight is critical. On the other hand, stationary or industrial camera systems may have more flexibility in size and weight but might demand higher durability. Environmental conditions also play a significant role in slip ring selection. Outdoor camera systems, for example, must contend with temperature extremes, moisture, and dust. Slip rings with an appropriate IP rating, such as IP65 or higher, can ensure reliable performance under these conditions. For mobile or drone-mounted cameras, vibration and shock resistance are equally important, as these systems are often exposed to significant mechanical stress during operation.

The materials used in slip rings directly affect their longevity and performance. Gold-to-gold contacts are often preferred for camera systems due to their excellent conductivity and ability to reduce noise during signal transmission. For applications requiring high rotational speeds or heavy-duty use, multifiber brushes can offer enhanced durability and efficiency.

Finally, for unique or complex applications, modular or custom-designed slip rings may be the best option. Many manufacturers provide tailored solutions to meet specific technical or environmental needs, ensuring that your camera system operates at its best.

Choosing the right slip ring requires a balance of technical, environmental, and operational considerations. By focusing on the unique demands of your system and collaborating with slip ring manufacturers when necessary, you can ensure reliable performance, high-quality signal transmission, and extended system life for your camera applications.