The key to guaranteed results and operating performances, the choice of motor is fundamental for the success of a printing machine. Italian large format digital printer producer […]

The key to guaranteed results and operating performances, the choice of motor is fundamental for the success of a printing machine. Italian large format digital printer producer NoeCha has chosen the Tecnotion technology, distributed in Italy by Servotecnica.

Ironcore Tecnotion linear motors are designed with technologies and forms that minimise the “cogging” effect (to learn more about cogging, go to What is cogging?). This characteristic, combined with the performances these motors deliver, which make them ideal for printing, and for industrial applications in general, is the reason why NoeCha has decided to use them on its machines.

Large format printing technologies

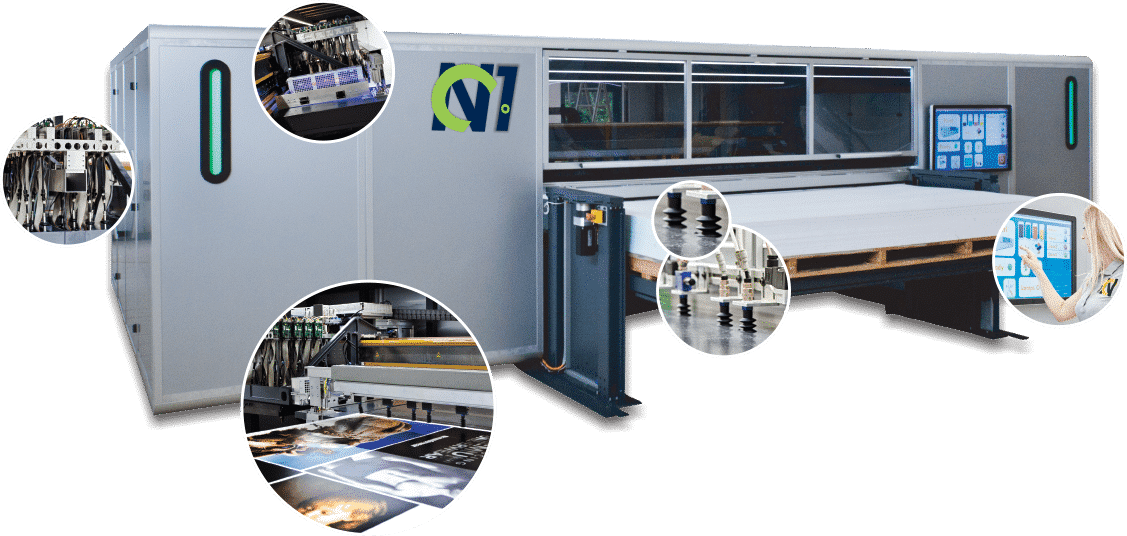

Printing on any type of material and surface, from paper to plastic and from ceramic to metal; large industrial printers are able to meet this need.

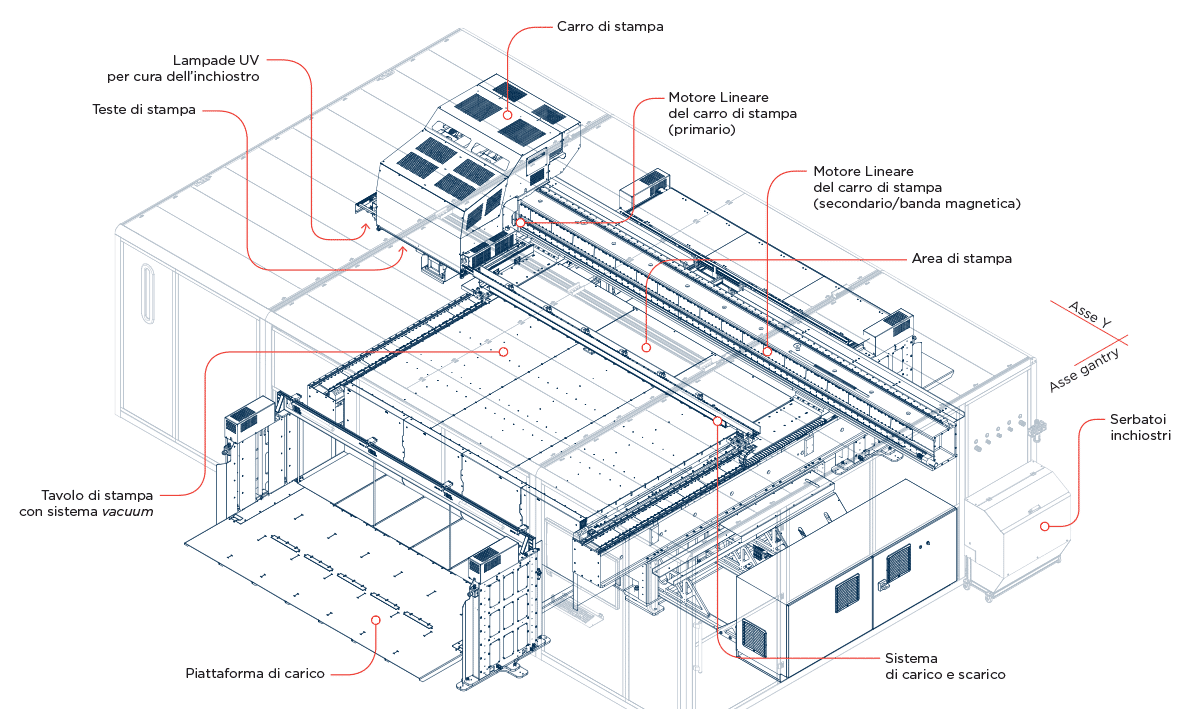

Flatbed digital printers have a large, flat printing table, on which the material for printing is placed. Their printing system is able to function on different types of substrates and on widely different materials – paper, PVC, fabric, ceramic, wood, metal, etc. – while the bed height adjustment also enables printing on multiple thicknesses.

Normally, printers of this kind use a UV curable ink, which is polymerised by UV lamps installed in the print heads, to fix it to the substrate and provide a uniform, very shiny result.

The heart of the printing machine

The central element of any printer is the print head, on which the finished product quality depends. Print heads have evolved rapidly over the years in terms of resolution (now, standard types have resolution of 600 dpi with about 2500 nozzles, while the most high-performing provide 1200 dpi with about 5000 nozzles) and droplet ejection frequency (over 100 kHz is quite normal), as well as the number of greyscale levels possible per dot. A medium-high level industrial printer is normally assembled with print heads of 600 dpi fitted with over 2500 nozzles, and with a native ejection frequency of 30 kHz.

During processing, the print head is moved by the printing carriage motor, which moves it from left to right and vice-versa to enable it to scan the page in horizontal swathes, while other motors feed the paper at right angles to the print head travel direction. As well as the head travel speed and the ink droplet ejection frequency, the greatest possible stability must also be guaranteed. In fact, to enable excellent quality image production, the individual ink droplets leaving the nozzles must be very precisely positioned within the printing matrix, and this can be achieved by using a linear motor to drive the printing carriage. The choice of the most suitable type of motor for these needs thus becomes crucial.

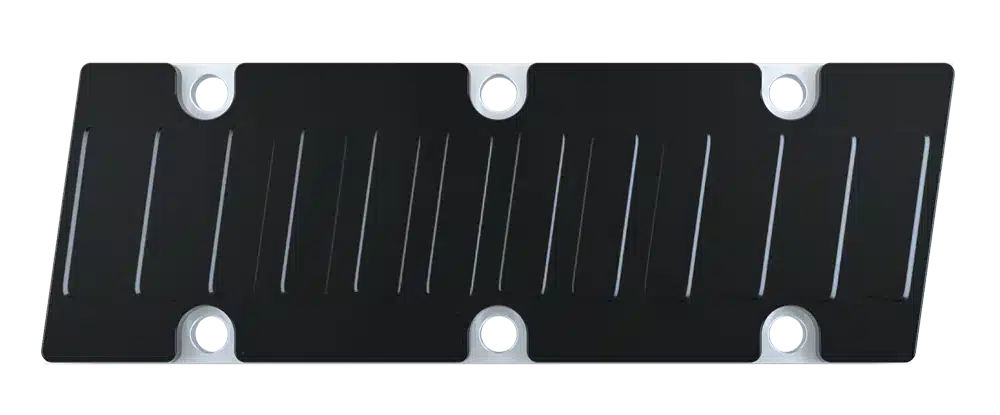

Low cogging ironcore motors

Ironcore linear motors are particularly ideal for installation on large format printers. In fact, they are able to move heavy weights like the printing carriages of industrial machines. An industrial print head weighs about 500 grams, and the weight of the supporting electronics, also installed on the carriage, has to be added to this. Considering that every single printing carriage is fitted with numerous heads – on average 16, but some carriages even have 32 or 64 heads, depending on printer format – it is easy clear that the total weight of a printing carriage may easily exceed 150 kilograms.

Ironcore linear motors are therefore the ideal solution. However, they do have one drawback: they are intrinsically subject to disruption due to parasite forces generated by the iron in the motor, an effect known as “cogging”.

Tecnotion, the specialist company that builds the linear motors distributed by Servotecnica, has overcome this problem by developing and designing ironcore linear motors with a special geometric form that minimises this type of disruption. This makes them ideal for applications on large format printers: it is no coincidence that the world’s top printing machine producers choose Tecnotion linear motors for their printers.

Fast and stable

In a printer, the motor must also guarantee high performances, including high-speed operation and stability. Once again, the linear motor is the best solution from various points of view.

Inkjet printers generally operate at printing speeds over 500 lin.met/h, and these values require carriage travel speeds from about 1.2 up to 2.4 m/s.

To offset the physical error in print nozzle placement intrinsic to print heads, nozzle droplet ejections are distributed over several passes (interleaving) until the whole printing matrix has been completed; therefore, the printing carriage motor must move faster for a given ejection frequency. Although this technique provides considerable improvements in printing quality, it makes extreme demands on the mechanical parts and the motor, requiring sharp accelerations, continual reversals in printing carriage direction and, at the same time, extremely constant speed during droplet ejection (table 1).

| Number of passes | Carriage speed at 20 kHz@600 dpi | Carriage speed at 30 kHz@600 dpi |

| 1 | 847 mm/s | 1270 mm/s |

| 2 / 4 / 8 / 16 | 1694 mm/s | 2400 mm/s |

Having a motor capable of keeping the speed constant (low ripple) is therefore fundamental for correct drop placement between passes, avoiding undesirable overlaps which would cause large variations in the printing colour.

The multipass technique is also used for high-resolution printing on low-porosity substrates in materials such as PVC, glass, ceramic, etc. With materials of this kind, in singlepass printing the droplets would not have time to dry, in spite of the UV lamps, and would collapse into one another, blurring the images. Spreading the ejections over multiple passes, alternating the droplets at the odd and even passes, for example, ensures that the ink has sufficient time to dry.

Not just “multi”

Rapid, constant motion are not only crucial in the multipass technology; with the latest print heads, these two factors are also vital in singlepass printing. The print head nozzles are arranged in several rows (figure 3) over an area of several millimetres, so perfect alignment during the pass is fundamental to avoid “jagged” lines.

Due to this “multi-row” arrangement, it takes 16 different droplet ejections (strokes) to produce a line with perfectly aligned dots on the various substrates (figure 4).

| Feeding pixel pitch | 42 µm | 42.1 µm | 42.2 µm | 42.3 µm | 42.333 µm | 42.4 µm | 42.5 µm |

| Pattern tendency |

|

|

|

|

|

|

|

One final, equally important, benefit is the stability over time which the linear motor ensures. Unlike a belt drive system – still used on some low-price printers – the linear motor does not require maintenance of any kind. Performance remains exactly the same from the day of installation to the end of the printer’s lifecycle.

With the linear motor, acceleration of 10m/s² – the maximum permitted by the print head – can be achieved regardless of carriage weight.

NoeCha: a small company with a global vision

Founded in 2010 by Marco Baio at Capriate San Gervasio, Bergamo, Italy, where it is still based, NoeCha S.r.l. (www.noecha.com) is a high-tech company that designs, builds and sells large format digital UV-LED inkjet printers with high-end performances. From the outset, the company has aimed to offer the digital graphic arts market innovative technologies, with solutions able to set new standards of quality and productivity.

The owners’ determination to grow their business has won them the support of the 035 Investimenti S.p.A. group, which invests in the equity of small enterprises focused on expanding their operations. For NoeCha, this growth means winning the trust of the international markets, especially in Europe, where the company currently exports its printers. However, it is also setting its sights on the overseas markets, thanks to the support of an excellent network of specialist dealers.