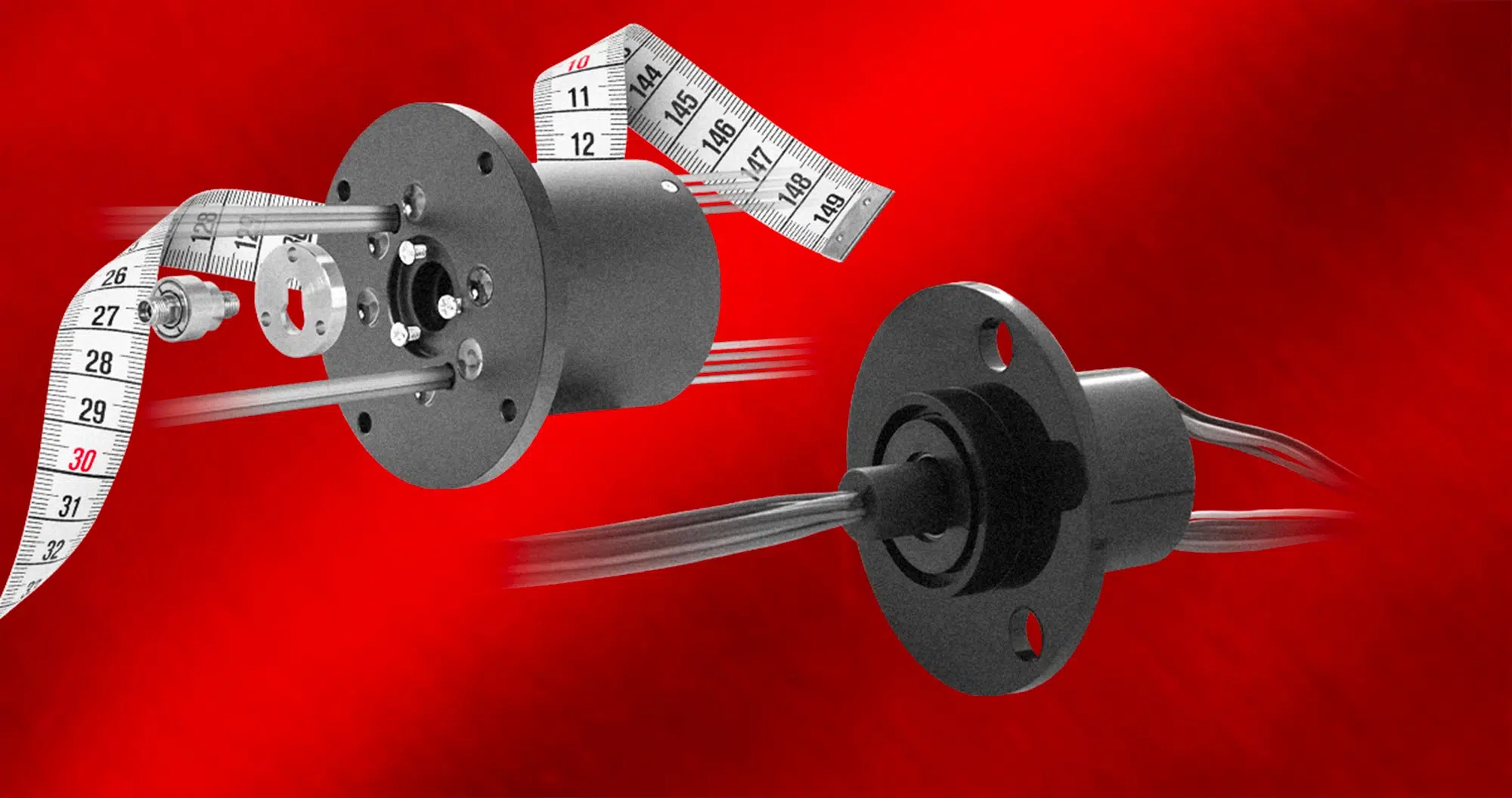

Off-the-Shelf Slip Rings Off-the-shelf (standard) slip rings are pre‑manufactured models with fixed dimensions and circuits. They are generally lower cost and faster to obtain than custom […]

Off-the-Shelf Slip Rings

Off-the-shelf (standard) slip rings are pre‑manufactured models with fixed dimensions and circuits. They are generally lower cost and faster to obtain than custom units. In contrast, custom-built rings require design and engineering, so they typically take weeks. Custom designs incur a premium in design and manufacturing efforts, making off‑the‑shelf units less expensive up front. Standard slip rings are widely used in many industries. They commonly appear in industrial automation and packaging equipment, anywhere a rotating assembly must transmit power or signals. Off-the-shelf models also power video surveillance, providing 360° rotation of power and video lines. In short, standard slip rings appear in routine machinery, such as factory robots, rotary tables, and security cameras, benefiting from their ready availability and affordable pricing.

- Ready-made designs: Standard slip rings use fixed connectors and mounts (flanges, bores, threaded rotors), making them easy to install.

- Fast delivery, low cost: Stocked slip rings can be delivered in a few days, whereas custom units may take 1–6 weeks.

- Common applications: Off-the-shelf slip rings are used in robotic assembly, packaging (to provide constant power/signals to rotating parts), and in PTZ CCTV/security cameras (for continuous rotation of video and power).

Custom Slip Rings

Custom slip rings are engineered to fit very specific or extreme requirements. They are not “one-size-fits-all.” Instead, designers tailor every aspect, including size, number/type of contacts, connectors, materials, etc., to the application. Typical drivers for customization include space constraints, unusual electrical specs (e.g., extra high voltage or many circuits), and environmental or regulatory demands. These rings are often used in aerospace, defense, robotics, and medical devices where bespoke designs are necessary. Custom rings cost more and take longer. Because each unit is effectively a new design, customization adds engineering time. The perceived high cost of custom rings is a major concern. In practice, custom slip rings can be several times more expensive than stock models and may require weeks of design and testing. Lead times for custom assemblies are often on the order of 10-12 weeks or more.

- Tailored performance: Custom rings include only the features needed, e.g., special bore sizes, extra circuits, or unique connector types, ensuring optimum performance. They can incorporate advanced elements like encoders, built-in heaters, EMI shielding, and mixed-signal contacts.

- Specialized applications: These rings appear in high-end fields such as aerospace testing rigs, medical imaging machines, and robotics where reliability is critical.

- Higher cost, longer lead: Custom designs incur extra engineering. Compared to stock

Electrical Compatibility and Signal Transmission

Slip rings must match the electrical and data needs of the system. Standard slip rings typically provide common power and signal paths (e.g., AC/DC power lines, analog signals, encoder feeds). Many stock models support fieldbus and Ethernet protocols, and some modules have dedicated channels for digital data or video. For routine automation uses, a standard slip ring often suffices. Custom slip rings handle exceptional electrical demands. They can be engineered for very high voltages or currents and specialized signals. Custom designs may add numerous signal channels and high-voltage power lines. Some configurations also include RF and Ethernet channels in compact packages. Slip rings can even incorporate fiber-optic rotary joints for multi-gigabit data if needed.

- Standard support: Off-the-shelf slip rings usually handle typical power (tens to hundreds of volts, several amps) and common signal buses (analog/digital). They can carry Ethernet or control signals.

- Custom extensions: Custom designs add capacity or technology. Examples include high-voltage circuits (up to 1000 VAC), high-frequency RF channels, or extra data channels. Precision applications may require ultra-clean signals, so custom rings can use low-noise contacts and shielding to avoid interference.

Environmental Sealing and Durability

Standard slip rings often have basic environmental ratings, but high-end stock models can be rugged and IP-rated. Waterproof/dustproof units (e.g., IP65 or IP68) are available for harsh settings. Manufacturers often use corrosion-resistant materials such as stainless steel or special coatings for outdoor or marine use. Custom rings are tailored for extreme environments. If off-the-shelf protection isn’t enough, designers can add features. Custom slip rings can incorporate O-ring seals, purged housings, or special lubricants to handle vacuum, salt spray, extreme temperatures, or biohazards.

- Off-the-shelf ratings: Standard slip rings are offered in IP-rated versions (e.g., IP65, IP68). Waterproof capsule rings are often marketed for outdoor cameras and wind turbines.

- Custom enhancements: When needed, rings are modified for extra sealing or materials. Custom builds may add advanced seals, specialized lubricants, and high-grade alloys to survive water, dust, salt, chemicals, or extreme temperatures.

Signal/Data Transmission Considerations

Slip rings must preserve signal integrity. Off-the-shelf rings provide standard data paths (some include Ethernet or video circuits), but they have finite bandwidth. For most automation and CCTV uses, stock rings suffice (many support fieldbus or EtherCAT). However, high-bandwidth or noise-sensitive tasks often push toward custom solutions. High-speed video (like 4K or HD-SDI) or fiber-optic links require specialized slip rings or rotary joints to avoid degradation. Custom high-speed rings are available for demanding signals. These may integrate RF channels and coaxial lines to meet specialized requirements. Custom rings for test or computing equipment may incorporate high-speed Ethernet or USB channels with matched impedance. In wireless or radar systems, rotary joints may support microwave frequencies. In all cases, off-the-shelf slip rings handle “typical” signals, but extremely high data rates or precise analog signals usually require a custom or specialty design.

Summary

Off-the-shelf slip rings are pre‑engineered units that are cheaper and faster to procure than custom rings. They are widely used in industrial automation and rotating camera systems. Custom slip rings are reserved for specialized or high-performance tasks and involve extra cost and lead time. Technical aspects like voltage range, sealing, and data transmission vary depending on the design. Slip rings are typically rated for common power/signal circuits by default but can be customized to meet extreme environmental or signal-integrity requirements.